STEAMLINE

PROJECT OVERVIEW

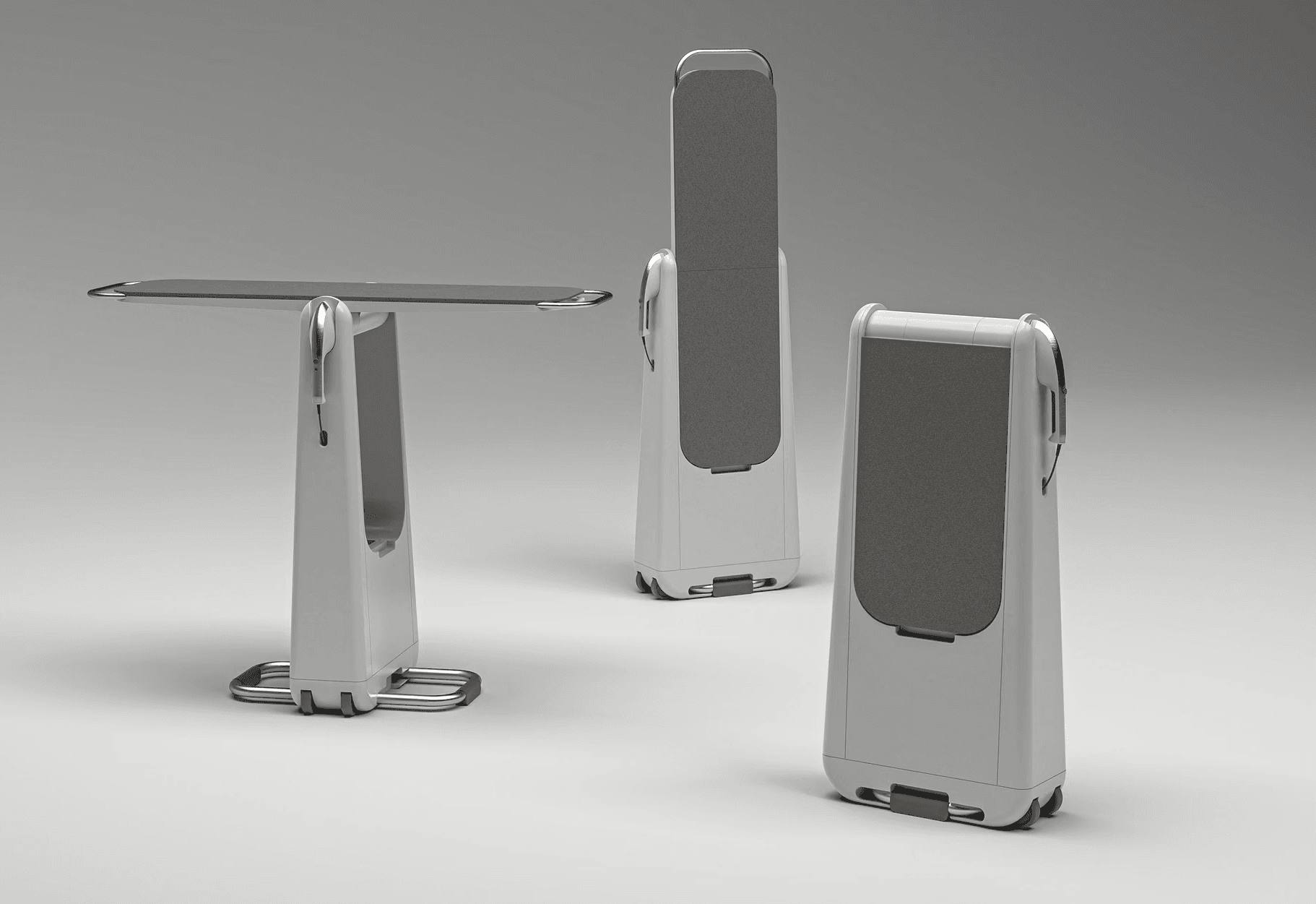

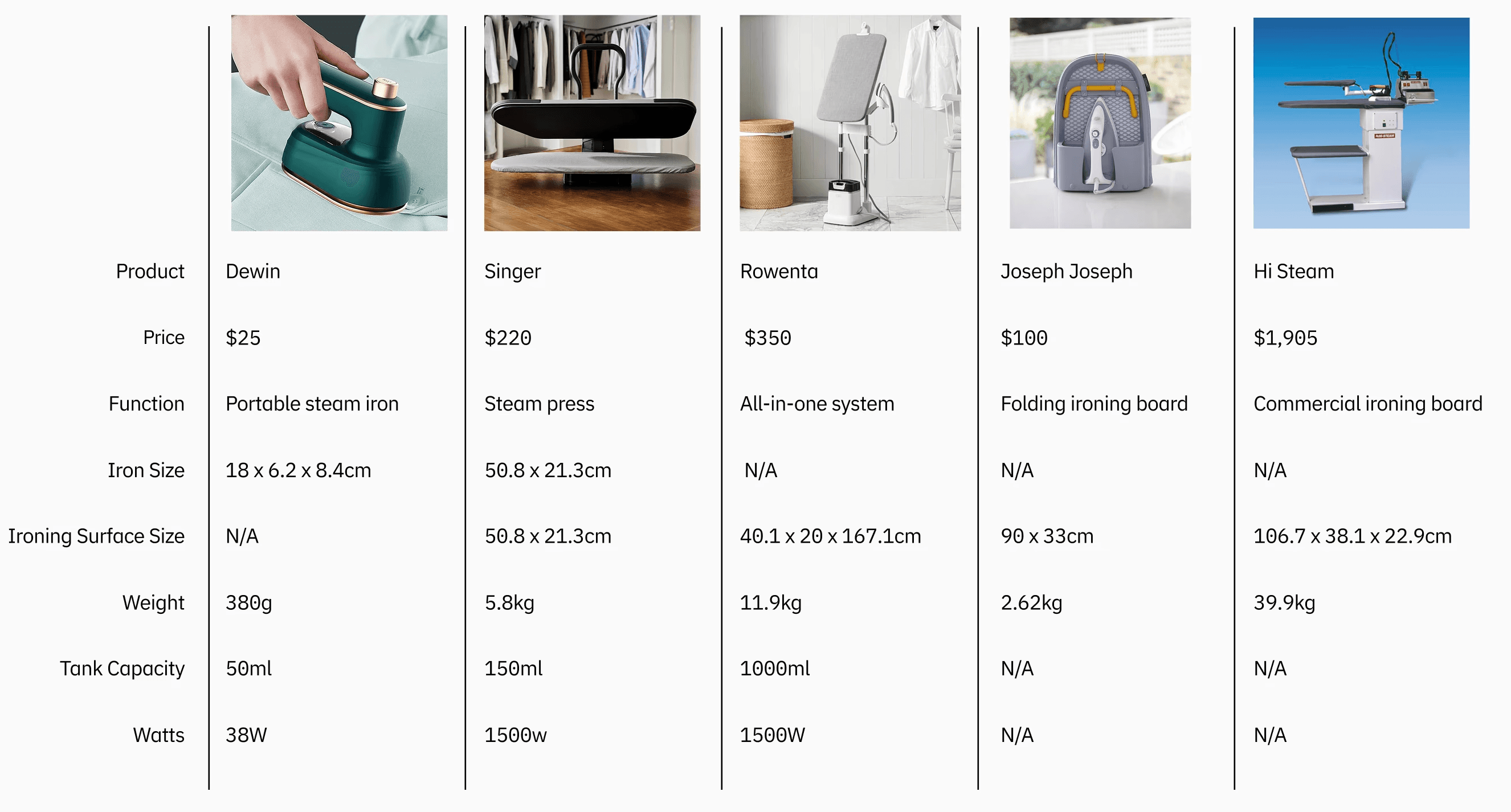

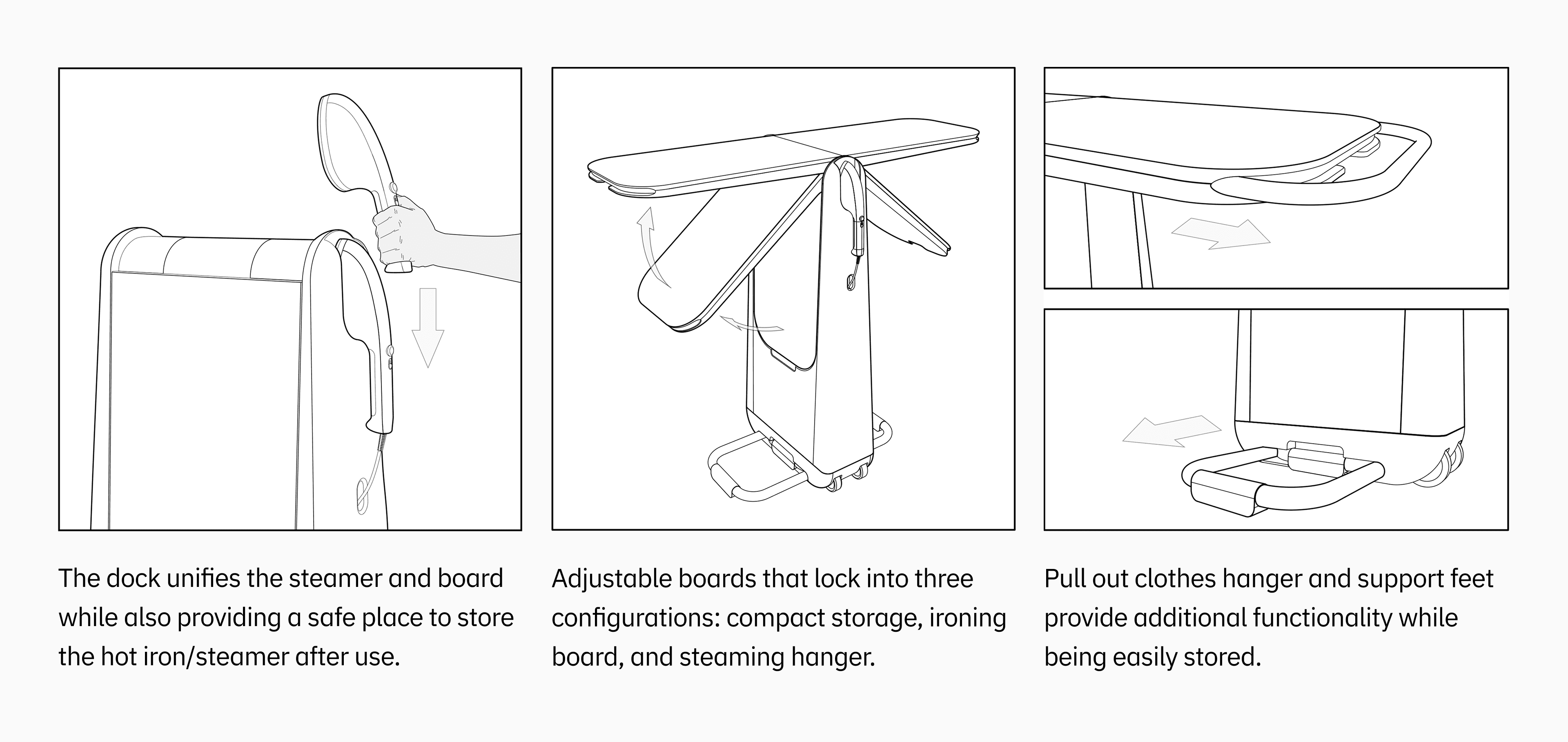

Steamline is an ironing and steaming station that provides a compact and versatile all-in-one solution to your garment care needs. Steamline mitigates the tedious tasks found in traditional ironing systems through its innovative features that encourage efficiency and organization.

TIMELNE

5 Weeks

November–

December 2025

TEAM

Matthew Li

Charlie Johnson

TOOLS

Rhino 3D

Keyshot

3D Printing

Illustrator

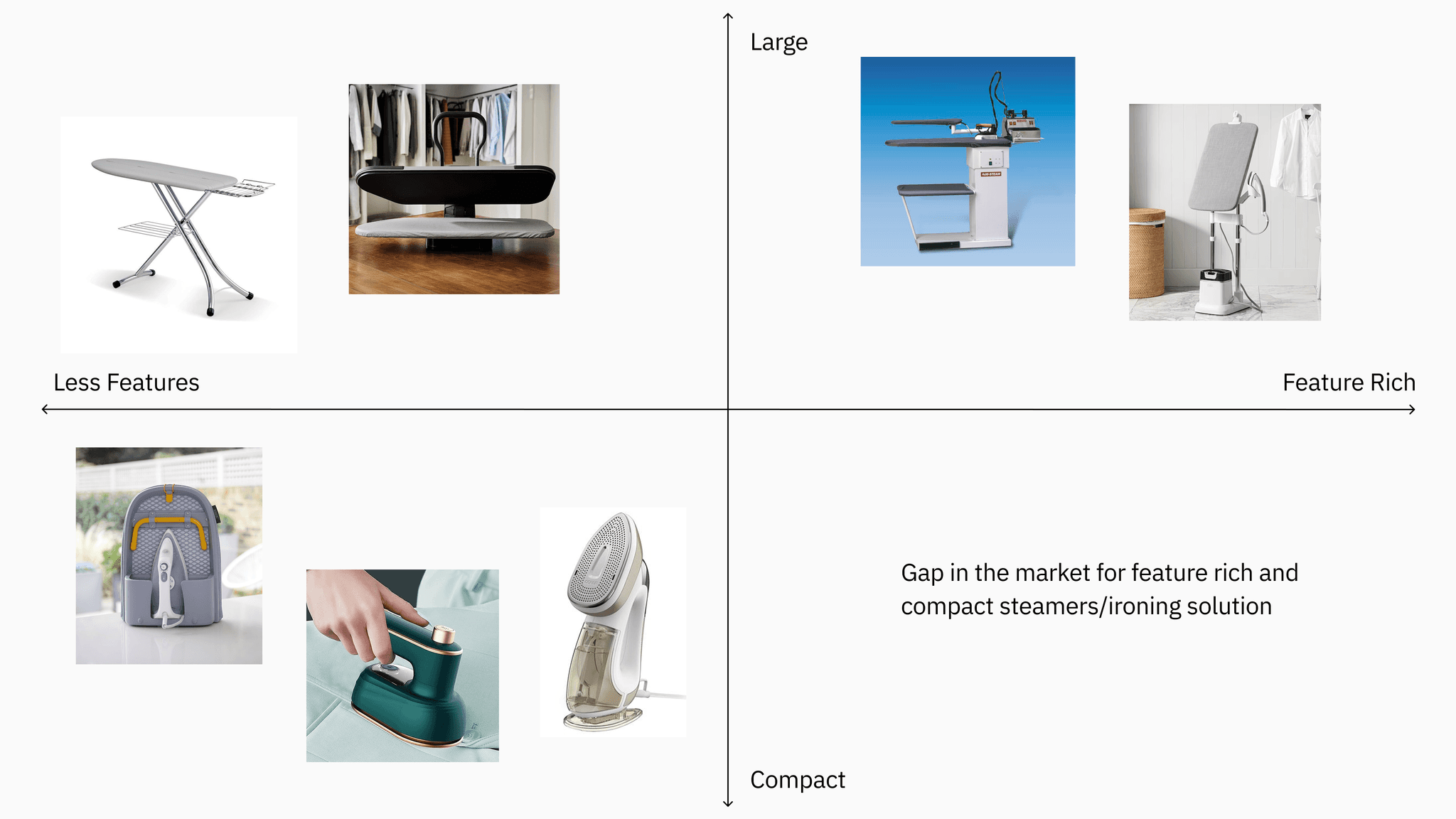

Market Analysis

ANALYZING MARKET TRENDS

Growing popularity of steamers over traditional irons.

Shifts to smaller living spaces lead to demand for space efficient products.

Increased demand for convenient solutions of common tasks.

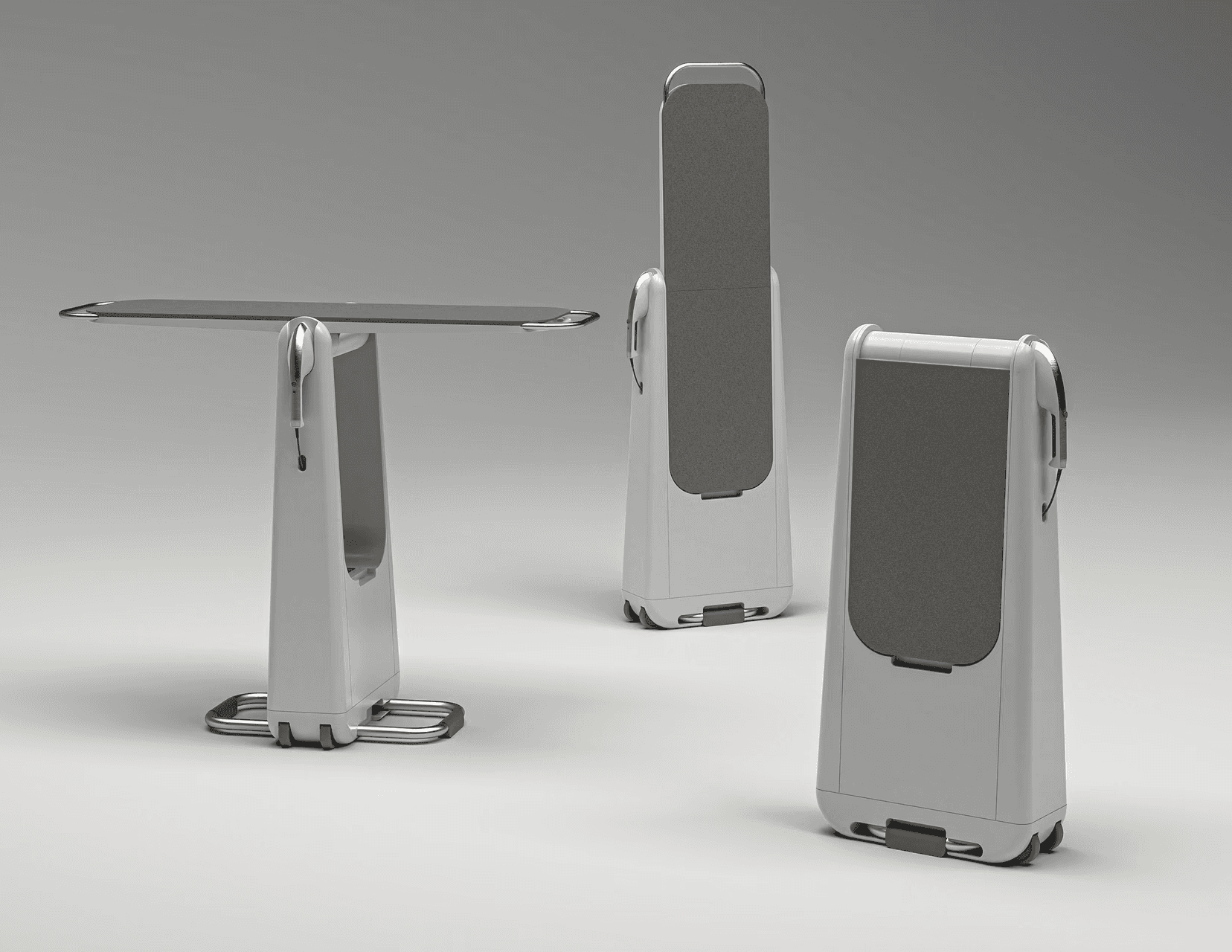

Task Analysis

OBSERVING THE IRONING PROCESS

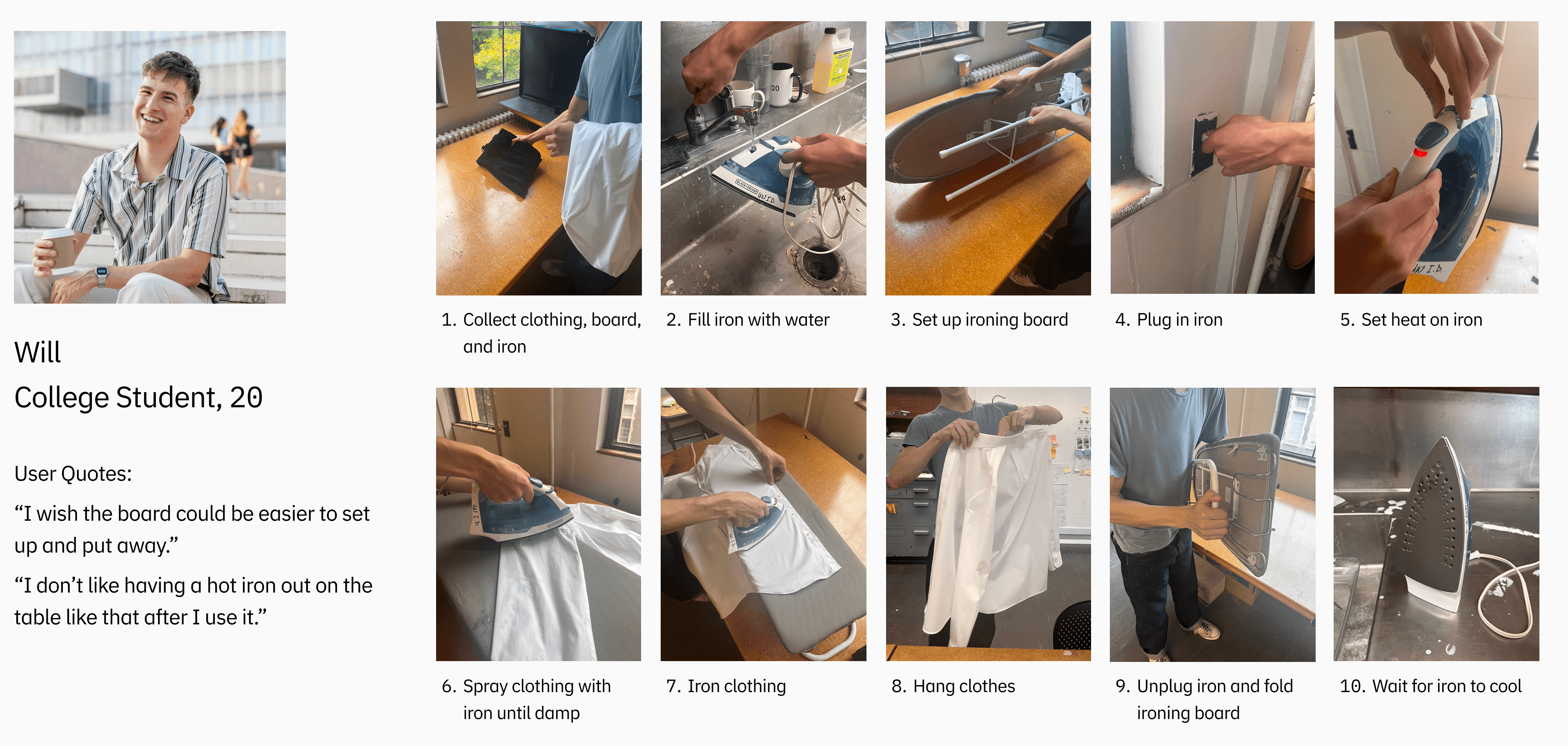

Benchmarking

EVALUATING EXISTING PRODUCTS

Interviews

UNDERSTANDING THE USER

USER 1

Financial Advisor, 50

Key Takeaways

Would like having a product that can steam and iron

Wants somewhere to hang clothes after ironing

Doesn’t like having to setup ironing board each time

Finds having to fill up the water tank each time annoying

USER 1

Financial Advisor, 50

Key Takeaways

Filling the iron with water is inconvenient

Ironing board doesn’t fold up nicely and takes up a lot of closet space

Setup feels like a lot of work for just a few clothes

TAKEAWAYS

Pain Points

Filling up the iron each time detracts from the overall enjoyment of the ironing process.

Setting up and collapsing the ironing board each time is tedious.

The numerous things needed to iron and steam effectively cause difficulty when storing.

How might we…

Create a compact steaming and ironing solution for apartment residents while improving safety, organization and efficiency in small spaces.

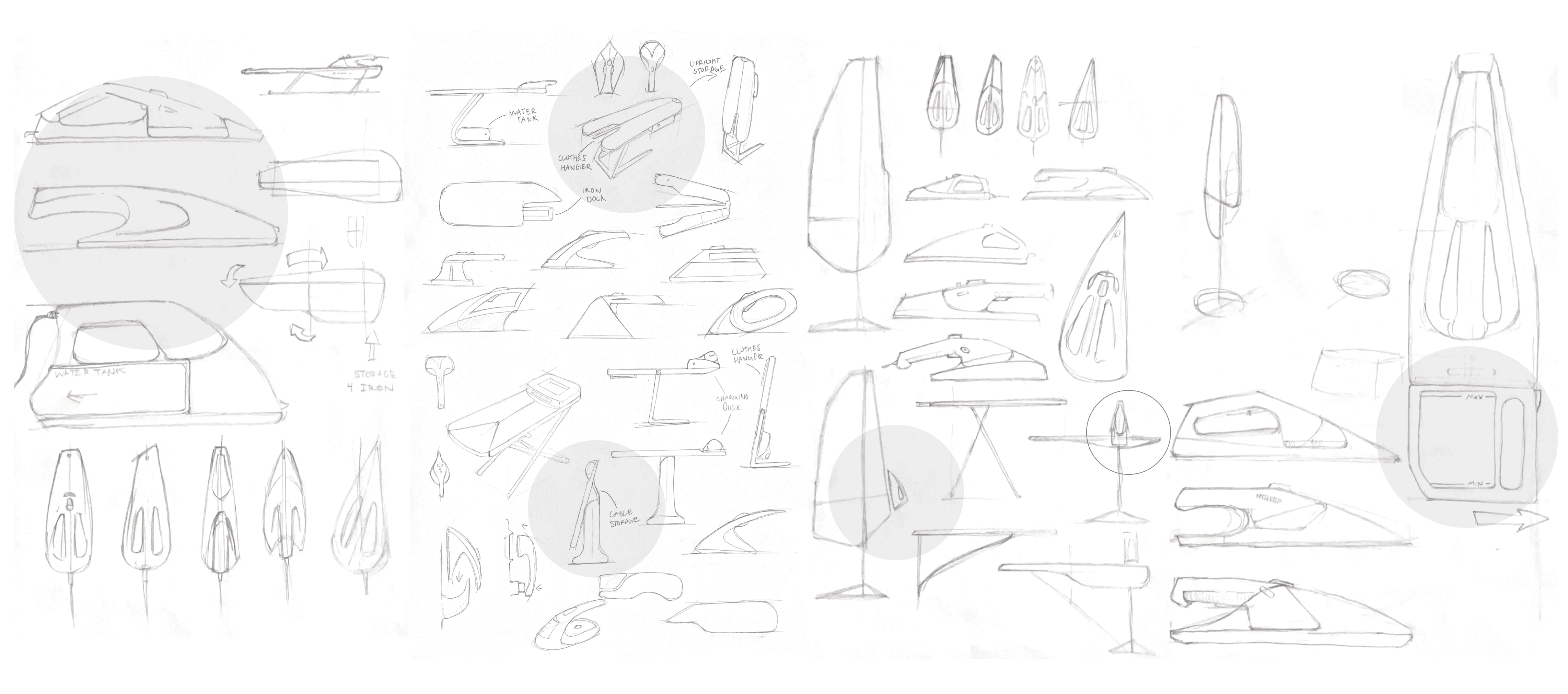

Ideation

BRAINSTORMING A SOLUTION

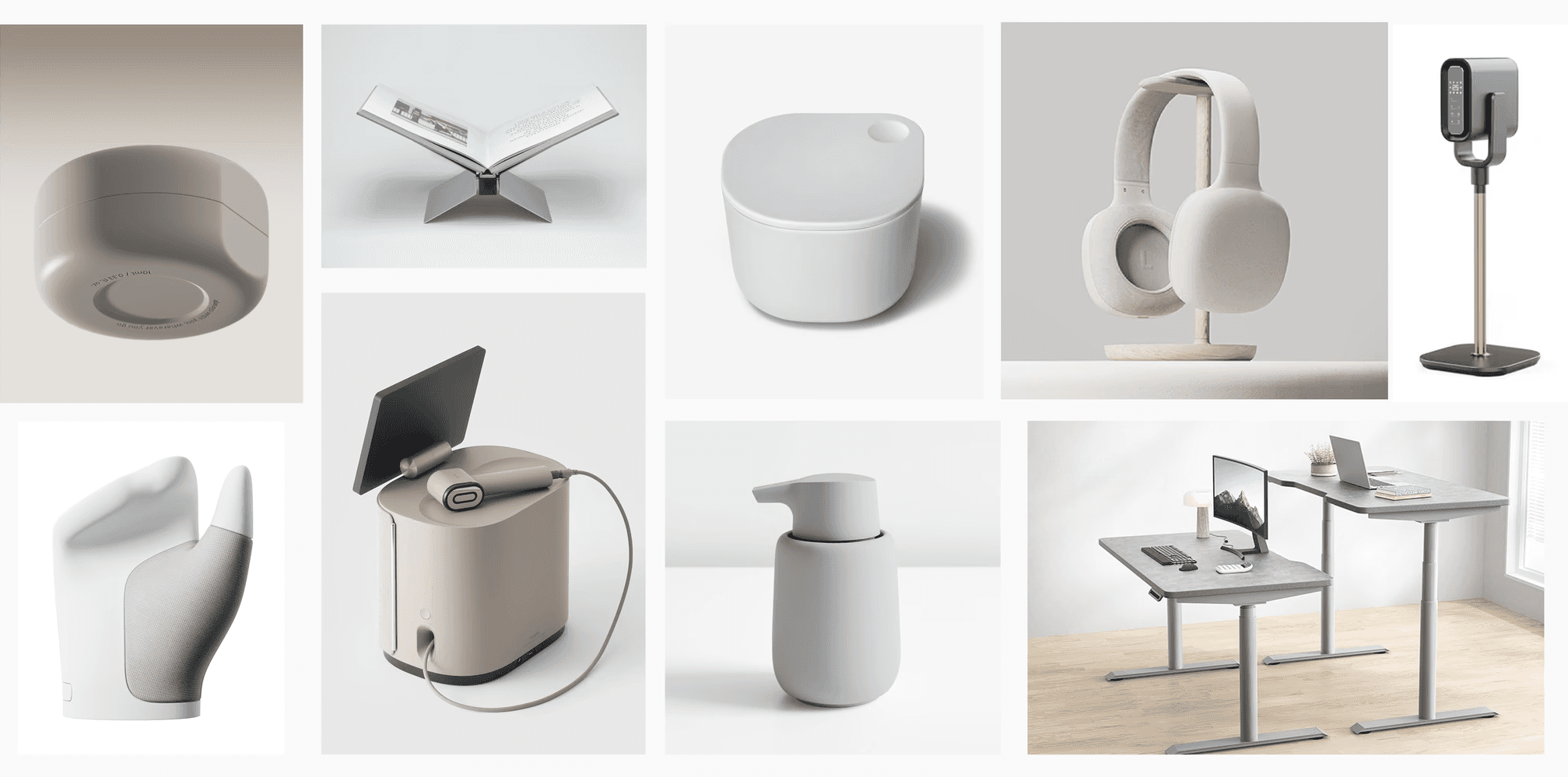

Mood Board

EXPLORING CLEAN AND ROUNDED FORMS

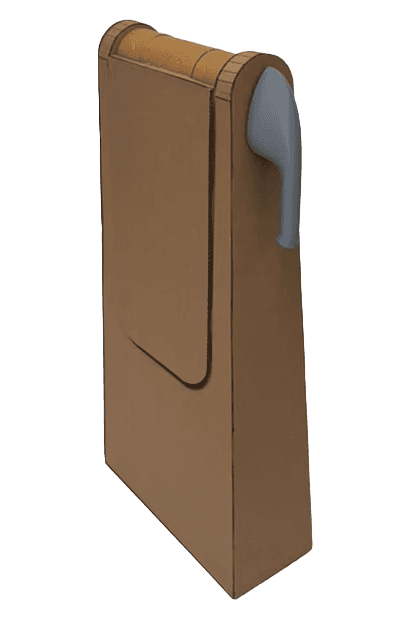

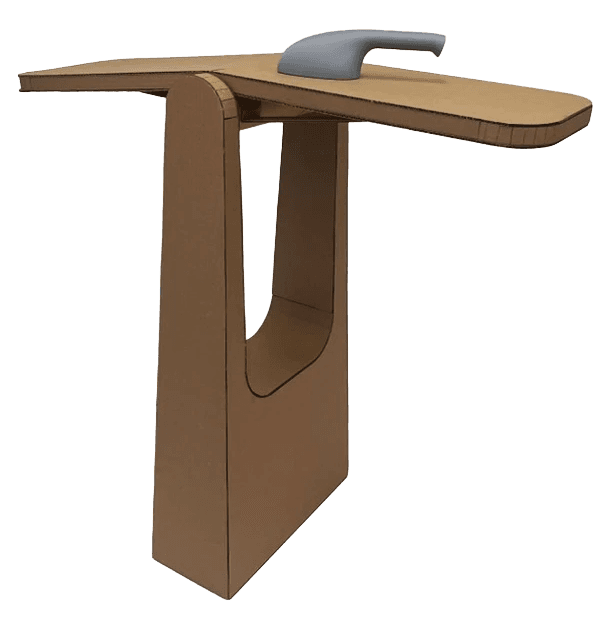

Low Fidelity Prototypes

TESTING STEAMER FUNCTIONALITY

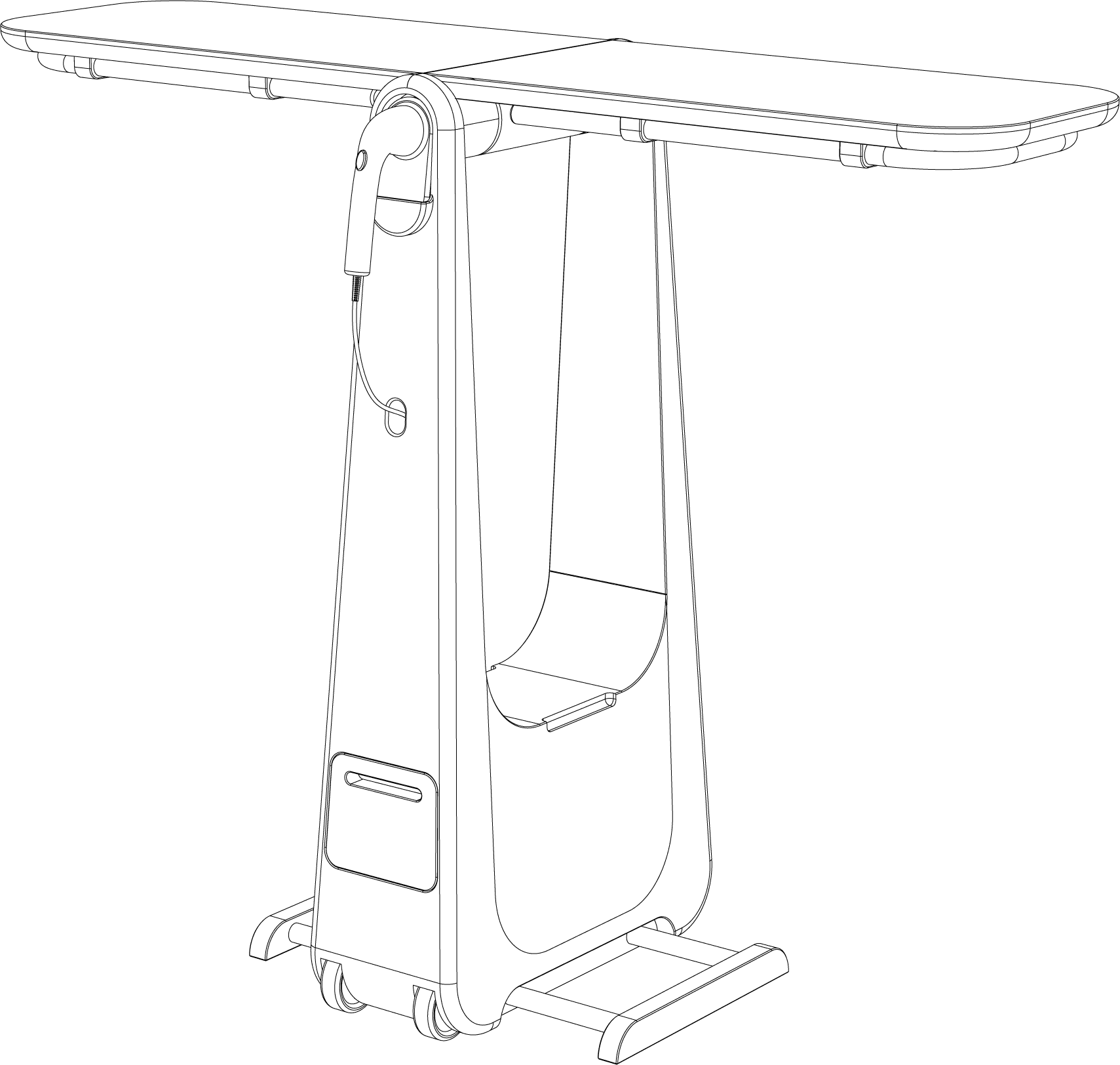

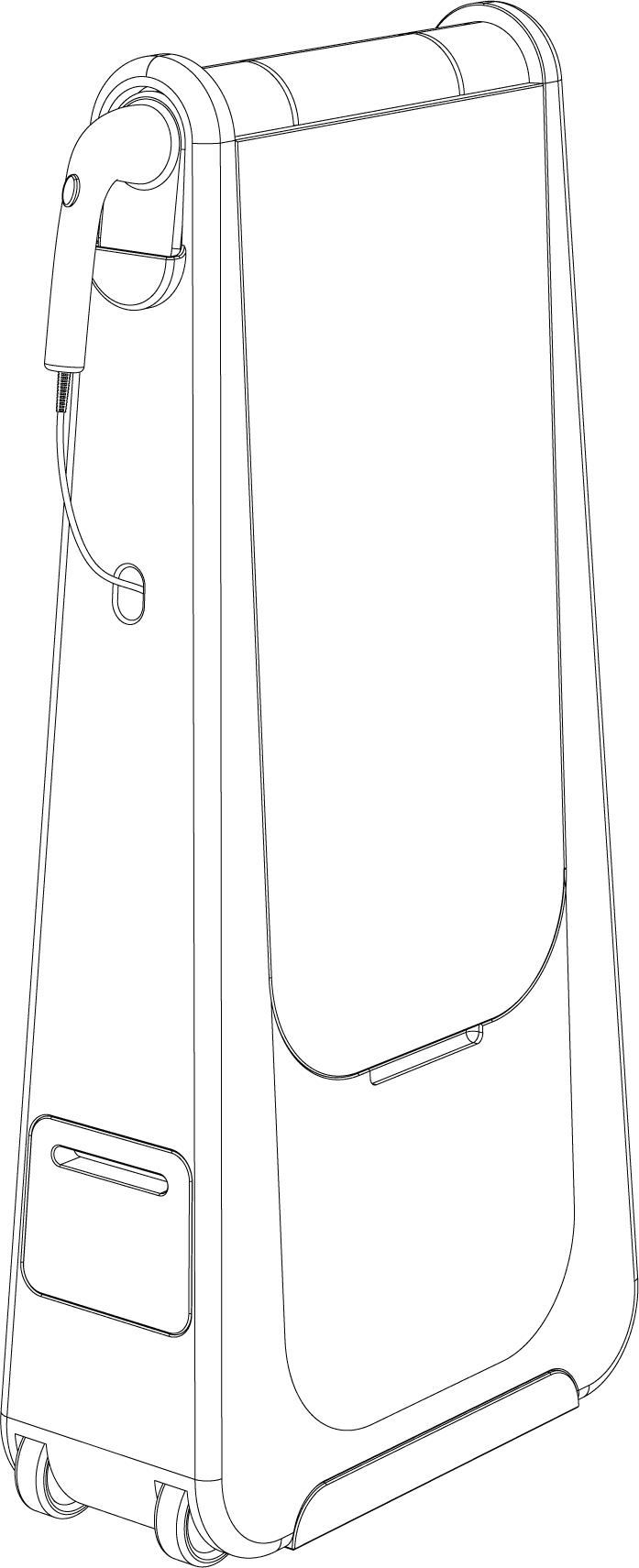

Rough CAD

ROUGH VISUALIZATION IN 3D

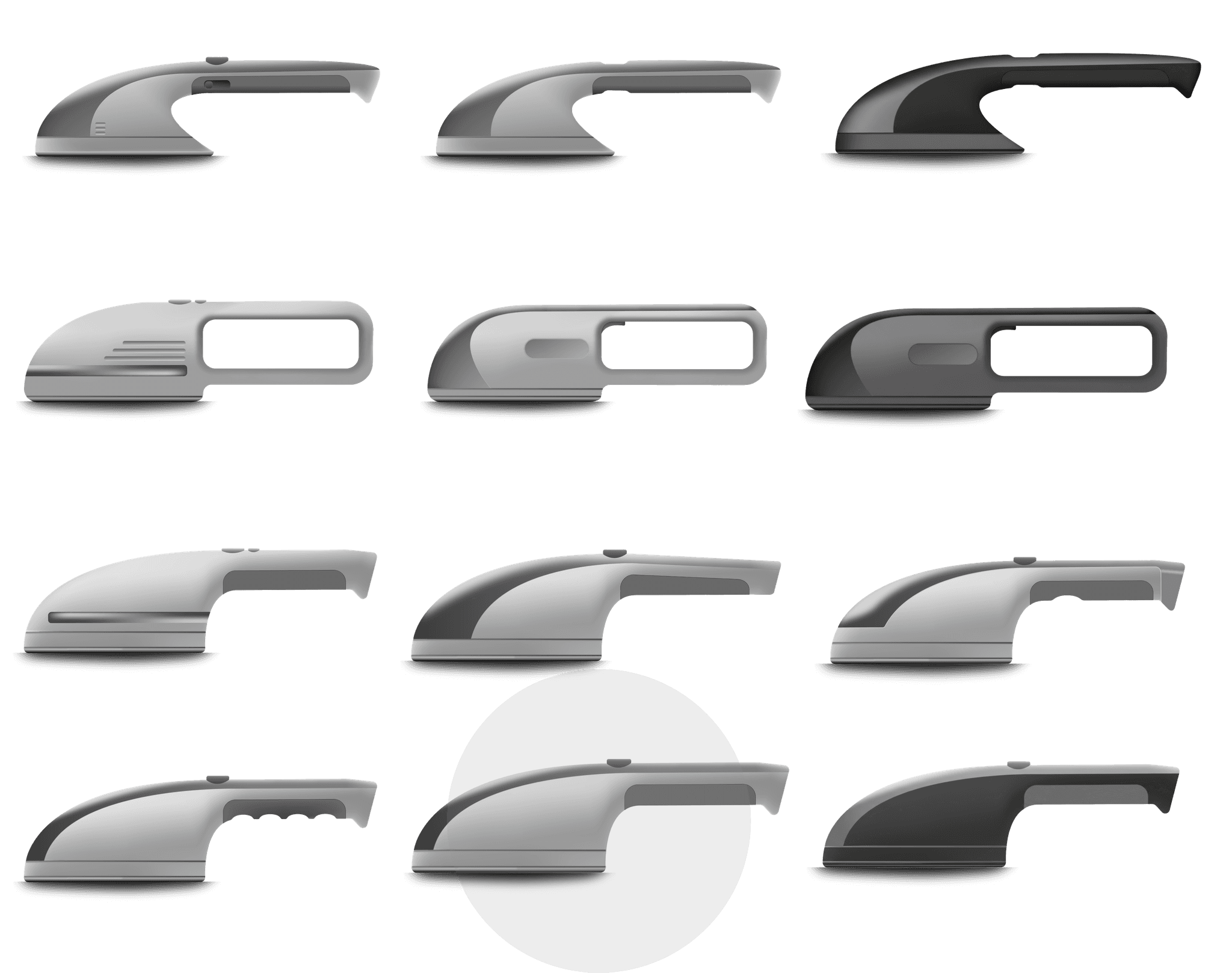

Orthographic Renderings

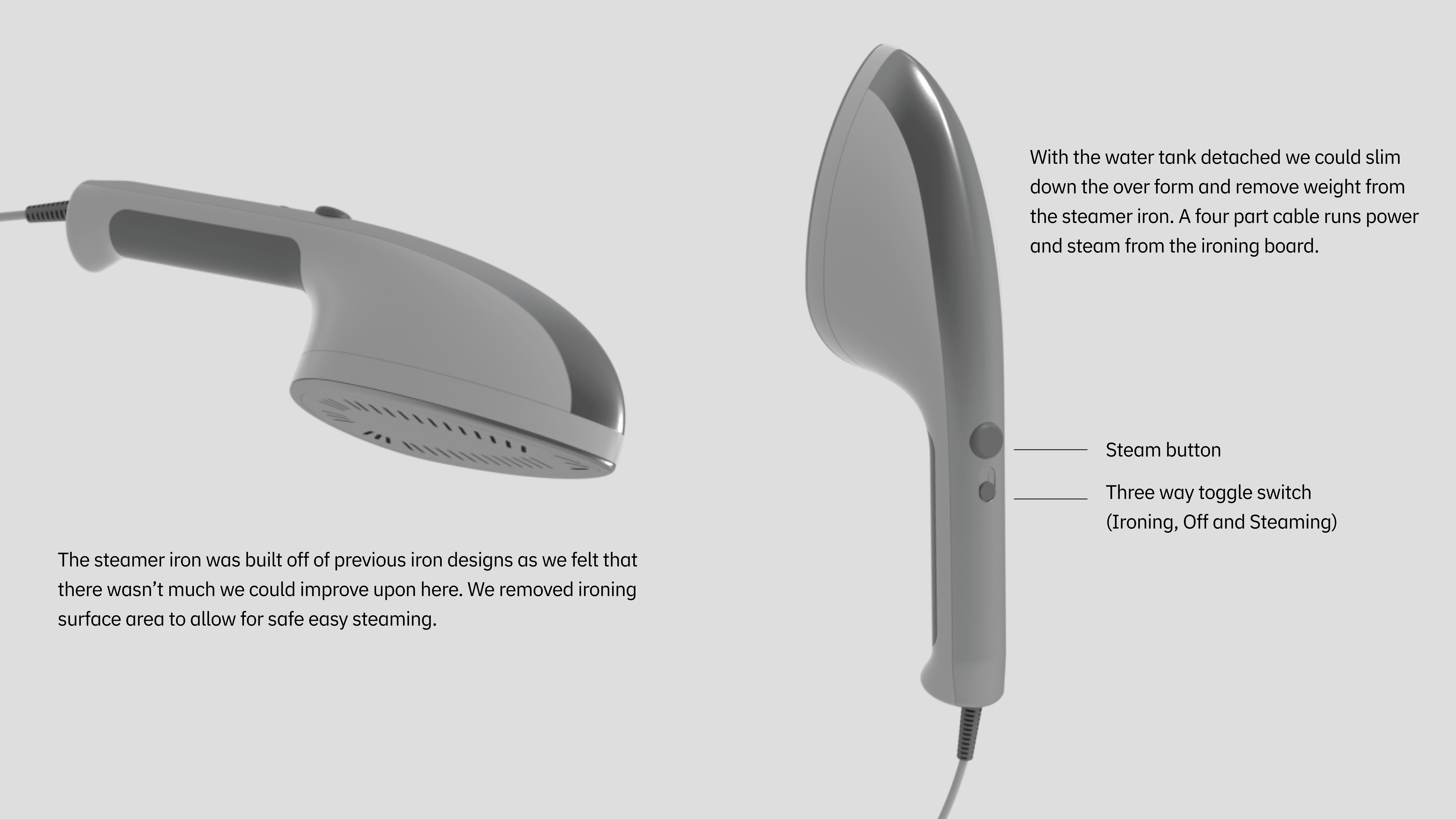

STEAMER FORM ITERATION

Final Prototype

TESTING ERGONOMICS

Introducing

STEAMLINE